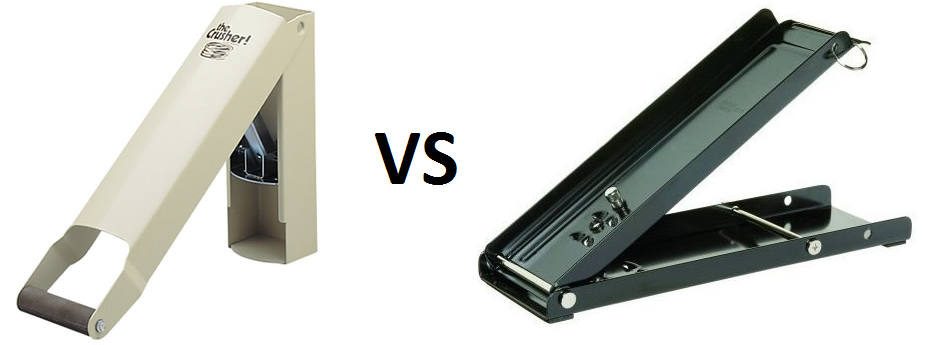

When choosing a can crusher you will have to choose from a horizontal or vertical fixture and that is a tough call to make if you have not tried them both out as both those types have their advantages and disadvantages and some people like one but others like the other style better.

When choosing a can crusher you will have to choose from a horizontal or vertical fixture and that is a tough call to make if you have not tried them both out as both those types have their advantages and disadvantages and some people like one but others like the other style better.

Horizontal Can crusher

Horizontal can crushers are those devices that work in a horizontal position mounted on your desk or are operated on the floor. These horizontal crushers also include some horizontal models that are mounted on top of recycling bins specially made for these fixtures so you have a wide range to choose from. These horizontal crushers usually are easier to operate and they take up less space than those vertical models as they do not need large levers to work properly and they use the force of gravity in your favor.

These Horizontal can crushers come in two models where one is hand operated but the other is foot operated so there is no single answer that could state all their advantages as each of these groups has different operation metrics. But in general these Horizontal crushers are small, very compact and will usually be easily mounted of any horizontal surface where you need crushing. If you can think of how scissors work by clamping together two horizontal plates then you can imagine how these crushers work and they usually crush those aluminum cans flat sideways that can be an advantage but can also be a disadvantage when you think that hose cans will take up 15 to 20 % more space overall than those puck sized thing that come out from Vertical crushers.

These devices are also not meant for heavy can crushing actions where you need to crush a lot of cans in a small amount of time as you need to get that can out yourself and there are usually no mechanisms that do this for you like in some vertical models. But as the durability goes these Horizontal crushers are usually made from metal so they are rigid and will ultimately outlast all plastic and wood models.

Vertical can crusher

Vertical can crushers are those devices that can be mounted vertically on your wall or some wooden boom as well as on some recycling bins on the side of them. These crushers are the main crusher type and you will find many different models from a lot of manufacturers that make these fixtures. These Vertical can crushers are usually designed in a way that use some cleaver hinges or pistils to transform a circular motion that you do with the handle into purely vertical motion to crush those cans. But the best part of these crushers is that most of them use gravity to disperse of those crushed cans in a container underneath or in a box on any other recycling bin that you have.

Vertical crushers come in a wide range of materials from your typical plastic crushers to stainless steel models as well as wooden masterpieces so consumers will have great choice options and can choose the best model they like.

Vertical can crushers need to be mounded in place as the force that is needed to crash cans from the top downs is greater than crushing them sideways and if these crushers are not screwed in place properly they can break and even dismantle wall anchors if you drill them in too shallow.

So which one to choose?

After knowing both models you have to make the decision and it is not an easy one to do as each one of those styles is made for different occasions but most often you will choose those Vertical models because there are just so many of them and that widespread availability is very important. Horizontal crushers can be great in situation where you need to crush cans not that often and need to hide the crusher for the rest of the time or they can also be used on top of tall recycling bins where users can themselves crush those cans before throwing them in there. Ultimately it all comes down to your individual taste but if you cannot choose then I would suggest to go with those vertical models as they have a much wider selection.